Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

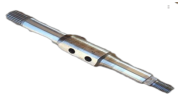

Concrete Pump Mixer Plate

We offer top-quality Concrete Pump Mixer Plates that are built to last. Our extensive inventory ensures that we have a full range of Concrete Pump Mixer Plates in stock and ready for quick delivery to our customers. If you have any questions or need assistance, please don’t hesitate to contact us. We are always happy to help and provide the best possible service to our customers.

Concrete Pump Mixer Plate Feature

[Hardness]: The concrete pump mixer plates are designed to withstand the harsh and abrasive forces of concrete mixtures. They have a high hardness rating, which makes them extremely durable and resistant to wear and tear. This means that they can handle the toughest jobs and last for a long time, even under heavy use.

[Durable Material]: The mixer plate is made of high-quality, abrasion-resistant steel that is specifically designed to withstand the extreme wear and tear of mixing concrete and aggregate materials. This means that it can handle the toughest jobs and last for a long time, even under heavy use.

Concrete Pump Mixer Plate Advantages

[Easy Maintenance]: The mixer plate is designed for easy removal and replacement, making maintenance and replacement quick and efficient if required.

[Easy Replacement]: The mixer plates are designed for easy removal and replacement, ensuring quick and efficient replacement that minimizes downtime and maximizes uptime for your concrete pump truck.

Application of Concrete Pump Mixer Plate

· Construction: such as building bridges, roads, and buildings.

· Infrastructure Development: such as road repairs and new construction.

· Mining Operations: Mixer plates are used to mix concrete for underground mining operations and tunneling.

· Industrial Applications: such as for mixing and processing chemicals, food production, and manufacturing.

How to Maintain Concrete Pump Mixer Plate?

1. Regular Cleaning: Clean the mixer blades and plates thoroughly after every use. Remove any accumulated concrete, dirt, or debris that might have accumulated after use.

2. Lubrication: Check and lubricate all moving parts, such as bearings and shafts, regularly to ensure that they are functioning optimally.

3. Check for Wear and Damage: Inspect the blades and wear plates regularly to ensure that they are not worn out or damaged. If you notice any signs of wear or damage, replace them immediately to prevent further damage to your equipment.

4. Check Hydraulic System: Regularly check the hydraulic system of your concrete pump for leaks, cracks, or any other damage. Address any problems immediately to prevent further wear and tear on the mixer plates.

5. Keep the Mixer Blades Balanced: If the mixer blades become unbalanced, it can cause excessive wear and tear on the plates. Check the blade balance regularly or after every use using a balancing kit and adjust if necessary.